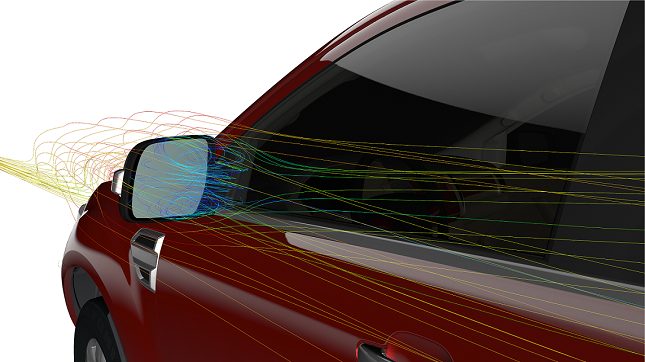

“The first thing I want to remove is the rearview mirrors. The car would look great without them.” However, Rob’s reason is quite scientific. He explained, “Rearview mirrors don’t contribute to the car’s aerodynamic design at all.”

For aerodynamic experts, rearview mirrors aren't the only thing they want to remove. To achieve aerodynamic perfection, Rob is willing to replace a host of unnecessary parts of the car, thereby increasing fuel efficiency and minimizing drag. A vehicle capable of smoothly directing airflow at every angle is the dream of any aerodynamicist.

This dream seems to have been realized by teardrop-shaped cars. This unique design allows air to move easily around the vehicle, while the elongated tail section helps to address the drag created by the vacuum that often forms when airflow leaves the roof and rear of the car.Conversely, there are many reasons why aerodynamic experts aren't the ones who decide everything, not just because nobody wants to drive a giant teardrop-shaped car.

At Ford, the final design of a vehicle must meet the diverse standards of numerous teams, including design teams, aerodynamic experts, and safety engineers. Because of this focus on driver safety, Rob himself acknowledges that rearview mirrors are an indispensable and irreplaceable component of any vehicle.

Teamwork

This compromise process is key to Rob and his colleagues' design development process. A designer who knows customer preferences may not necessarily guarantee aerodynamics. Similarly, Rob may offer the most aerodynamically optimal design suggestions, but these may not necessarily lead to best-selling products. Therefore, Rob's task is to optimize existing components to achieve the best possible aerodynamic efficiency for the vehicle.

Rob explained: “For example, on the Everest SUV, the outer edge of the front bumper has added spoilers. This design allows for the direction of airflow over the front of the vehicle and improves aerodynamics by 5%.”

Many current Ford vehicles are equipped with integrated air vents on the taillights, directing airflow away from the vehicle, rather than enveloping it as is typically done and creating additional drag – a rather clever detail that costs little to nothing in terms of aerodynamic design.

Technological advancements

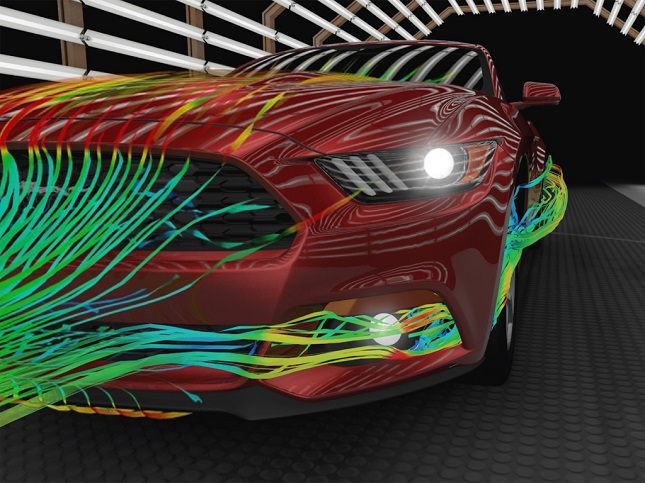

At Ford, the work of aerodynamics specialists has improved significantly thanks to developments in computing technology.

-Everest.jpg_2.jpg)

While wind tunnels remain a crucial part of aerodynamic engineering experimentation, advanced simulation equipment and machine models now allow Rob and his colleagues to easily test new designs directly on Ford's supercomputers. Although they don't replace the function of wind tunnels, these computer models provide a complementary tool capable of simulating hours of testing – something that was impossible about 10 years ago."If the experiment were conducted for two consecutive days, we could easily achieve 50,000 hours of simulation," Rob said.

The final design of a car is heavily influenced by the market it targets. While cars with lower ground clearance generally have better aerodynamics, ground clearance varies depending on the model and, especially, the flatness of the terrain in each area.“For example, in India, the roads are often quite rough, so the vehicle's ground clearance needs to be adjusted higher,” Rob explained. “Therefore, we need to consider all types of terrain across the entire country in the region.”

However, with more and more consumers wanting a fuel-efficient vehicle, every design change proposed by the aerodynamics team is given top priority. “Ford’s design team is now more receptive to our ideas,” Rob shared.In the era of electric vehicles, cars are increasingly moving towards more aerodynamic shapes. “For example, an electric car has less need for engine cooling, so the radiator grille can be designed to be significantly smaller, which is incredibly good for improving the car’s aerodynamics,” says Rob.

News: BK - HH

VI

VI EN

EN