To Viet

Some time ago, I accompanied a close friend to a wine cellar on Le Phung Hieu Street in Hanoi for a wine tasting. Being a wine connoisseur, my friend concluded that the Chilean wine we were drinking had been affected by high temperatures during storage or transportation, as the tannins had turned astringent and bitter.

Seeing my agreement, he asked, "Do you think we have the right to ask the waiter to change this bottle of wine?" I said, "I don't know about our country, but in the West, diners can only ask the waiter to change a bottle of wine if it smells like cork." Curious, my friend asked, "I've also heard of cork smell, but I can't picture what it smells like. When I have time, I should probably learn about the 54 basic smells and 12 potential flaws of wine so I don't fall behind."

Seeing my agreement, he asked, "Do you think we have the right to ask the waiter to change this bottle of wine?" I said, "I don't know about our country, but in the West, diners can only ask the waiter to change a bottle of wine if it smells like cork." Curious, my friend asked, "I've also heard of cork smell, but I can't picture what it smells like. When I have time, I should probably learn about the 54 basic smells and 12 potential flaws of wine so I don't fall behind."

Indeed, in 2009, the French conducted a large-scale study in the Bordeaux region on the phenomenon of cork odor in wine. The conclusion drawn from this study showed that 2-3% of Bordeaux wine bottles using liège corks were affected by this unpleasant odor. This also means that annually, 12-15 million bottles of Bordeaux wine suffer from cork odor, a significant loss. It's also important to know that among the many undesirable odors in wine, such as vegetal smells, rotten apple smells, alcohol smells, saltpeter smells, sulfur smells, earthy smells, rotten egg smells, etc., cork odor is the only one that allows diners to request a replacement bottle of the same type. While the aforementioned odors can be eliminated within a few minutes to 15-20 minutes after opening, cork odor will never be eliminated, even if the corks are left for many hours.

So what does cork smell like?

Cork odor is formed by the interaction of the chemical chlorine with fungi, phenols, and flavors present in the wine. It's a musty, pungent, and unpleasant smell, quite different from the delicate vegetal notes normally found in Sauvignon Blanc or Cabernet Sauvignon grapes.

Cork is made from the barked oak Quercus Suber, which grows at an altitude of 100-300 meters above sea level. This oak thrives in sandy soil in areas where winter temperatures do not drop below -5°C, with an average rainfall of 400-800 mm per year. Portugal is the world's largest cork producer with 670,000 hectares of barked oak, accounting for 30% of the world's cork production; followed by Spain with 480,000 hectares of barked oak.

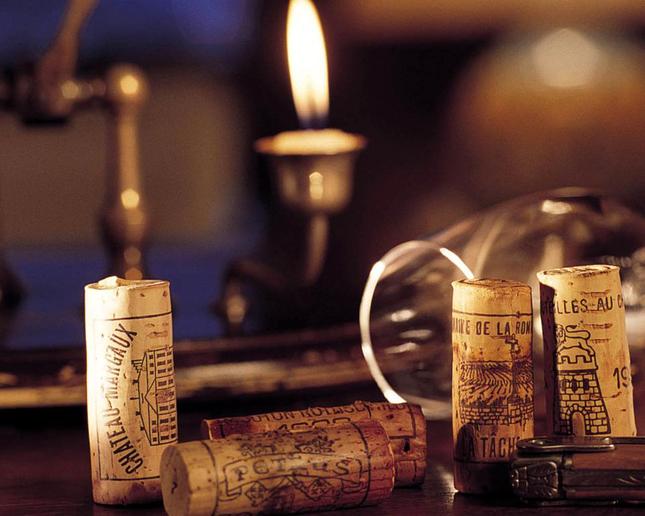

Battered oak bark is characterized by its lightness and buoyancy. Since ancient times, people have used oak bark to make lifebuoys and to secure fishing nets. Oak bark stoppers (liège) were used in winemaking and preservation from 500 BC to 500 AD. After this period, the collapse of the Roman Empire, constant wars, and stagnant trade led to the decline of oak bark. It wasn't until around 1600 that oak bark was widely used again in the wine industry, gaining a dominant position among all cork materials such as sawdust, oak bark chips, plastic, and screw caps.

The messages hidden behind it

The production of a cork is a laborious process. Each Quercus Suber oak tree must be at least 25 years old to provide us with bark 70 mm thick. When the Quercus Suber oak tree is 14 years old, workers begin stripping the first layer of bark, much like stripping cinnamon bark, but this layer is unusable in the wine cork industry and is discarded because it is too rough, coarse, and contains too much tannin. It takes another 12 years for the second, smoother layer of regenerated bark to be used for wine corks. Thanks to its excellent elasticity, oak bark is considered the best material for making corks. Oak bark contains 45% suberine (which provides elasticity), 27% lignin (a binding agent), 12% polysaccharides (a structural component), 6% tannins (also known as coloring agents), 5% rodes (a water-repellent substance), and 5% water, sugars, and minerals.

Although the oak bark is left outdoors in the rain and sun for two years after harvesting to stabilize its elasticity, and then placed in a vat of boiling water mixed with chlorine to kill parasitic bacteria before being sanded smooth and corked, some parasitic bacteria still survive in the tiny cracks of the oak bark and develop into TCA (Trichloranisole) or TTCA (Tetrachloroanisole) in the wine.

Just 4.6 nanograms of TCA or TTCA for stabilized wines, or 1.5 nanograms for Champagne, is enough to detect the cork taint.

That doesn't mean just anyone can perceive this aroma; it requires practical training through school or a course in wine tasting and quality assessment.

VI

VI EN

EN