THE SOUL OF THE GIANT LANTERNS

Many people know washi paper as an indispensable ingredient in making Japanese lanterns. In the summer, the city of Aomori is dotted with giant "warriors" parading through the streets. These enormous lanterns of various shapes are the centerpiece of the nearly 300-year-old Nebuta Matsuri festival. The festival takes place in the evenings, lasts for a week in August, and is one of the biggest seasonal events in Japan.

Local people spend months designing and producing these lanterns. Hiroo Takenami, a craftsman, said the outer layer of these "giant warriors" is made from...washi- A traditional handmade paper made from mulberry tree branches.

A giant lantern at the Nebuta Matsuri festival.

According to Takenami, the outer layer of modern lanterns is not entirely made of traditional washi paper, although there are still similarities: "We encountered torrential rains during the parade, and the rain damaged the traditional paper covering the lanterns. So we had to produce a type of paper that includes synthetic fibers to increase its water resistance."

That adjustment was necessary as the country still maintains traditional festival activities. Although today, machine-made paper has largely replaced the original handmade washi paper throughout Japan, in some towns, artisans still preserve the tradition of making handmade paper.

The outer layer of the modern lantern is not the original traditional washi tape.

It originated from the type of paper used for writing religious texts.

According to the Nihon Shoki, one of the oldest books in Japanese history, paper was introduced by Korean monks in the early 600s AD. At that time, washi paper was used to write Buddhist scriptures as Buddhism began to be introduced and embraced throughout Japan.

Over time, the use of stronger, more durable plant-based fibers, such as mulberry bark, developed. The paper's durability improved significantly, leading to the widespread adoption of this traditional method throughout Japan. Its strong texture and high absorbency make washi ideal for calligraphy and ink-based artwork.

Washi paper is ideal for calligraphy.

Furthermore, thanks to its excellent light-filtering properties and the strength of its interwoven fibers, washi is also used as a paper screen for doorways, a curtain, lanterns, and more. Not only is it versatile, but this type of paper is also very environmentally friendly. Unlike industrially produced products, washi is made from freshly discarded branches, eliminating the need to cut down entire trees. The washi production process also does not use chemicals, and the paper is biodegradable.

Washi paper is also used as a paper screen at doorways and windows.

However, during the Meiji era (1868-1912), when Japan underwent a period of Westernization, with the emergence of paper-based and mass-produced paper, washi began to decline, shifting from its everyday use to more artistic and traditional purposes.

It takes a decade to become an artisan.

One of the oldest washi paper-making centers in Japan is Mino City, which has a trading district dating back to the Edo period (1603-1868). Lanterns made by any local resident, from students and amateurs to skilled artisans, in Mino all use washi paper.

Takeshi Kano is one of eight renowned artisans in Mino whose skills meet the standards to produce handmade washi paper in its most original and traditional form (only 10% of all washi paper in Mino meets this standard). To be recognized, an artisan must undergo at least 10 years of training as a member of the Honminoshi Paper Preservation Association.

"Training the next generation of paper-making artisans in the modern era and passing on the craft's knowledge is crucial. We are both preserving this traditional craft and maintaining its financial viability," said Takeshi Kano.

Takeshi Kano is one of the eight renowned artisans who make handmade washi paper in Mino.

Authentic washi paper must be made entirely by hand...

Sharing about the washi paper-making process (honminoshi), artisan Takeshi said: "Authentic Mino washi paper must be made entirely by hand, using only three ingredients: mulberry branches, water, and a mucilage that helps increase the uniformity of the plant fibers when dispersed on the paper."

Essentially, the handcrafted process has been passed down through generations of artisans. First, they steam mulberry branches until they are soft enough to peel off the bark. The inside is then washed with river or stream water and dried in the sun for natural bleaching.

Next, the papermakers boil the bleached bark and then soak it in cold water, carefully removing dirt and dust. They soften the bark fibers by hand-beating them and then mix them in barrels with water and neri mucilage to form pulp.

Mulberry tree branches are one of the main components in making washi paper.

Washi paper is peeled after steaming.

It is then rinsed with river or stream water.

The ingredients are dried in the sun for natural bleaching.

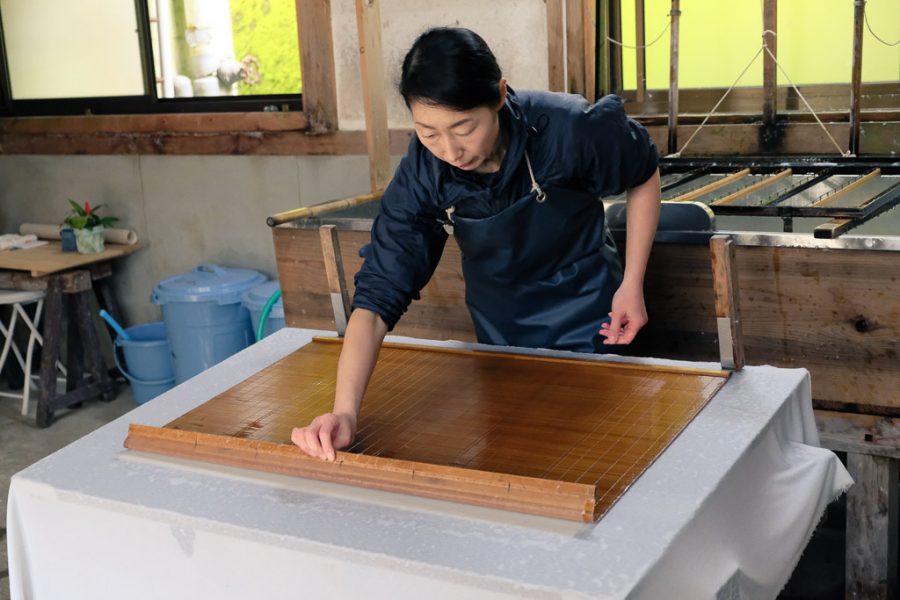

A wooden frame with hinges is used to form sheets of paper when immersed in cold water. The formed sheets of paper are then pressed overnight and left to dry on a board. This process takes several weeks to transform the pulp into paper.

The sheets of paper are "shaped" using a wooden frame.

It is then pressed overnight and left to dry on boards for several weeks.

In 2014, the unique washi paper-making tradition (honminoshi) in Mino City was recognized by UNESCO as an Intangible Cultural Heritage. Sekishubanshi (Hamada City) and hosokawa (Ogawa City) were also recognized with this title. "The people living in these communities are proud of their washi paper-making tradition and consider it a symbol of their local cultural identity," a UNESCO representative stated.

cultural values that endure over time.

Visitors to Mino City, the washi paper capital, can easily explore Japan's proud culture through contemporary craft shops showcasing traditional washi items such as clothing, bags, paper umbrellas, home decor, and postcards. Even the textile manufacturer Takebe launched reusable washi paper masks last year.

Business cards printed on washi paper.

Washi bags are eco-friendly.

At paper mills or historical buildings, tourists can participate in making washi dolls and other traditional handicrafts. In addition, some tours offer experiential visits to mulberry plantations, craft workshops, factories, and workshops where visitors can even try their hand at making washi paper.

In rural Japan lies the famous Washi Village of Echizen, home to over 60 washi paper factories, including many that produce handmade paper. Here, visitors can tour the Udatsu Paper & Crafts Museum, where artisans will guide visitors on how to make washi paper and also view and purchase various types of handmade paper famous throughout Japan.

Tourists experience making traditional washi paper.

With the development of a modern industrialized nation like Japan, traditional washi paper has been replaced by other types of paper with lower production costs. Although not the only type of handmade paper in the country, washi still holds a firm place due to its cultural value and environmental friendliness.

VI

VI EN

EN